ERP Integration with batch-based processes is old news.

I read recently that “The Defense Department has transitioned away from a 1970s-era nuclear command and control system that relied on eight-inch floppy disks.” Yikes! I thought some of our manufacturing partners were behind because they’re still using batch-based processes!

The old way of importing manually or through schedules is being replaced.

Waiting, waiting and waiting for today’s orders from your Supply Chain System.

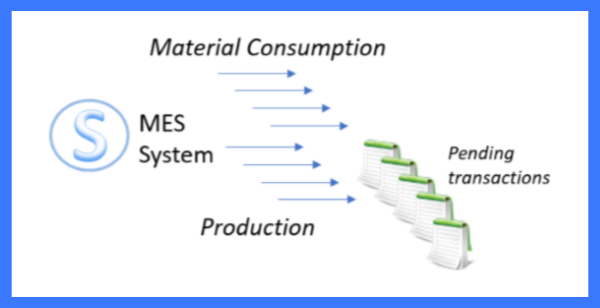

ERP-related activities happen in real-time, but the ERP system is completely unaware until later.

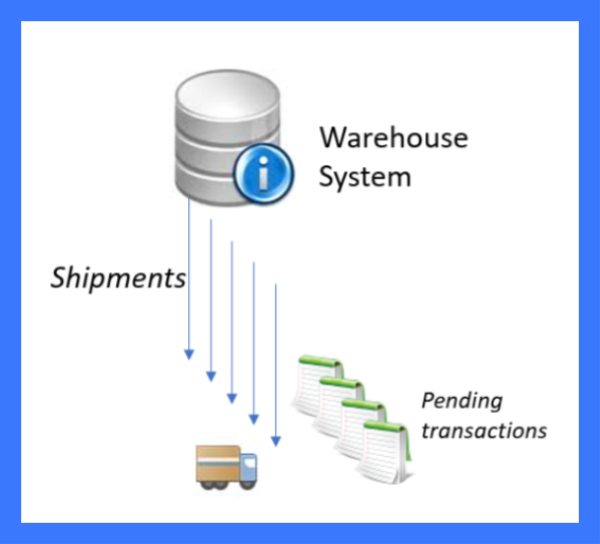

Shipments go out, but the ERP is not notified until much later.

ERP data is outdated and waiting. Until the day closes, data is yesterday’s shipments, yesterday’s consumption, yesterday’s production.

This was the old way – each component of your business system operating separately with data moving in batches at day’s end or on scheduled intervals. The result: timers, batches, lots (and lots) of waiting.

Welcome to the new way. Real-time transactional synchronization. All systems are up-to-date – always.

The new way is automated transactional integration which synchronizes and replicates data in real-time. This enables state of the art planning, scheduling, capacity planning, MES, and supply chain systems to work dynamically and always be up to date. Production activities process in real-time, enabling better reporting, resulting in more current, better informed reporting and decision making.

Real-time transactional Integration (with Microservices)

Supply Chain and other upstream and downstream systems receive data in real-time and are always current.

ERP is always current with shipments, consumption, production and all ERP-related activities. No schedules, no manual actions, no waiting, no delays.

Stuck in the 1980’s? Embrace the best practices of real-time transactional integration today!